Interpretation Of BLOSSOM CHEER

BLOSSOM usually means flowering, which is a very beautiful meaning, representing beauty, environmental protection, vitality and prosperity, and also represents that BLOSSOM is committed to providing environmentally friendly and beautiful products and services for many people who love nature and have a beautiful heart.

No matter what skin color we are, what language we speak, home is a safe haven for us, a place where we will miss no matter how far we go.

The balance between the protection of the ecological environment and the social and economic development is a topic familiar to every modern person, and this is often considered to be a trade-off relationship, that is, if the protection of the ecological environment is emphasized, it seems that economic development must be sacrificed . However, the development of science and technology has brought new changes to our development of circular economy, and we are very proud, because BLOSSOM CHEER has been making continuous and continuous efforts in this regard.

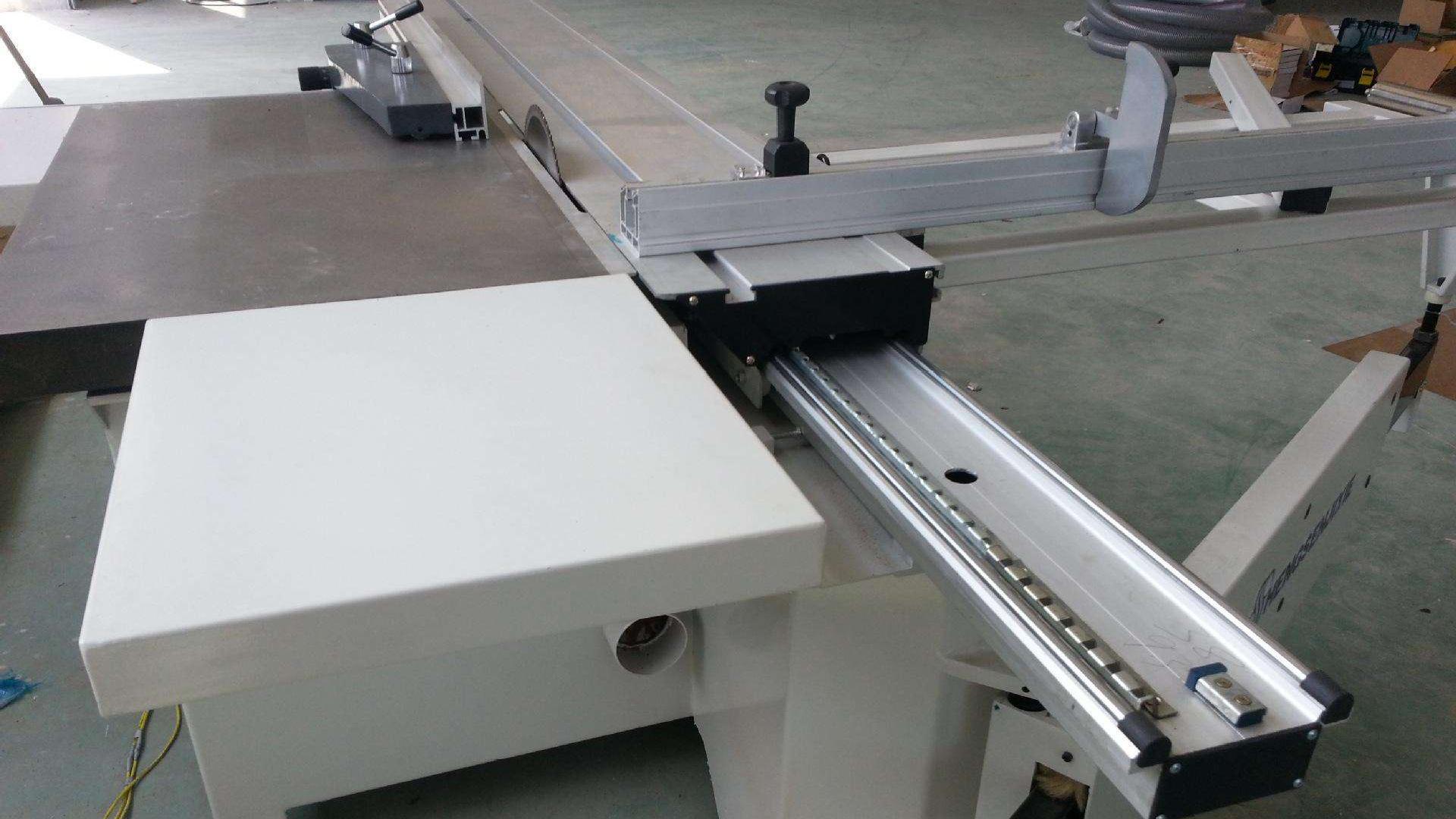

As one of the door materials, wood has natural texture, various shapes and rich styles, and is very popular for being able to produce various exquisite patterns. However, the growth of wood, especially precious wood, has a long growth cycle and limited resources, so BLOSSOM CHEER basically uses artificial recycled materials for wood, such as MDF boards, plywood, Tubular Particle Board (Tubular Chipboard), fire-resistant laminates, carbon crystal boards, etc.; at the same time BLOSSOM CHEER has actively joined the ranks of environmental protection actions, such as classifying raw material procurement, providing wood that cannot be in the protection catalog, and so on.

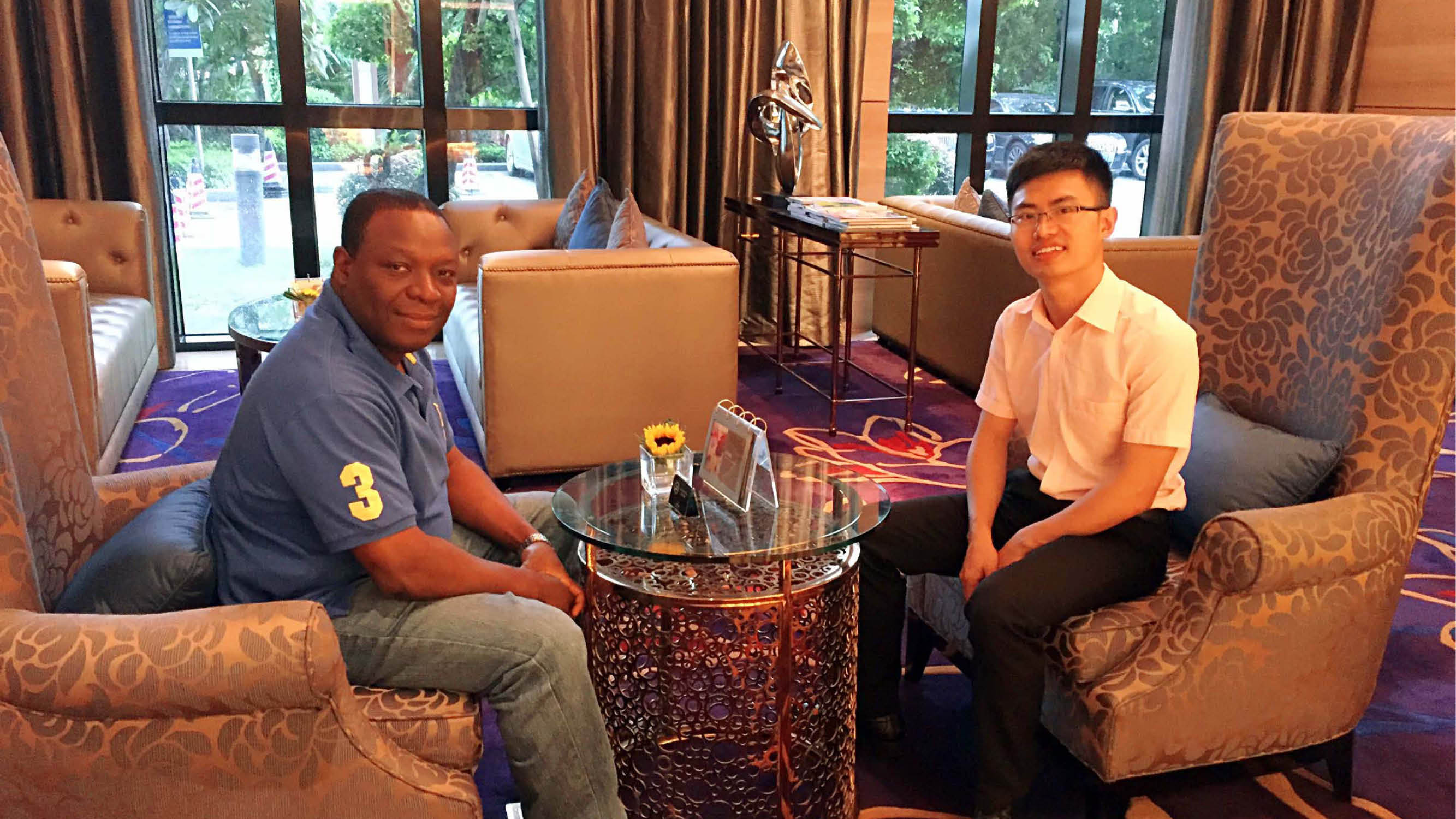

Customization needs are the same as the ecological environment in terms of diversity and complexity. Different users like different types, styles and requirements. Respecting the particularity of individuals and putting customers first is the first value of BLOSSOM CHEER, so we often need to visit or communicate on the spot. In-depth understanding of customer needs can truly do a good job in product customization. For example, in order to make the project installation easier, according to the requirements of a well-known shoe building in the United States, we deepened and realized the process plan that can install the door in 3 steps. For example, in order to make the high-end projects strong, beautiful and durable, we solved the risk of preventing deformation and made the products larger than 3.6 meters in size.

During the development of BLOSSOM CHEER, we have become friends with many customers who have achieved each other and grown together, because we are all supporting more families to create a better life. We are honored to cooperate with charities to help the homeless people who can return have provided high-quality and low-cost door and window products; we have also provided professional studio-level soundproof functional metal doors for brokerage companies. Because the customization of BLOSSOM CHEER door and window products has allowed more users to improve the quality of life, this is the real motivation and significance for us.

We respect those companies that have achieved success, and at the same time believe that emerging companies have great power when we pursue a mission together. Provide intimate care and protection for people who love their families! We have always adhered to strict product and service standards for the details and standards of customized door and window products, and we provide users with all-round support. Let us join hands and work together to achieve this common goal and create a better future for our society!