- Environmental friendly

No Glue & Zero Formaldehyde; Meet E0 (European Union) Standard

No Glue & Zero Formaldehyde; Meet E0 (European Union) Standard

0.1% Water Absorption; More Higher Than National Standard 0.5%

Not Support Combustion In Case Of Fire, Automatically Extinguishes After Leaving Fire

Top Level Antibacterial Durability (Grade), Antibacterial Rate Reached >99.9%

Formed Under High Temperature & High Pressure & Vacuum Conditions

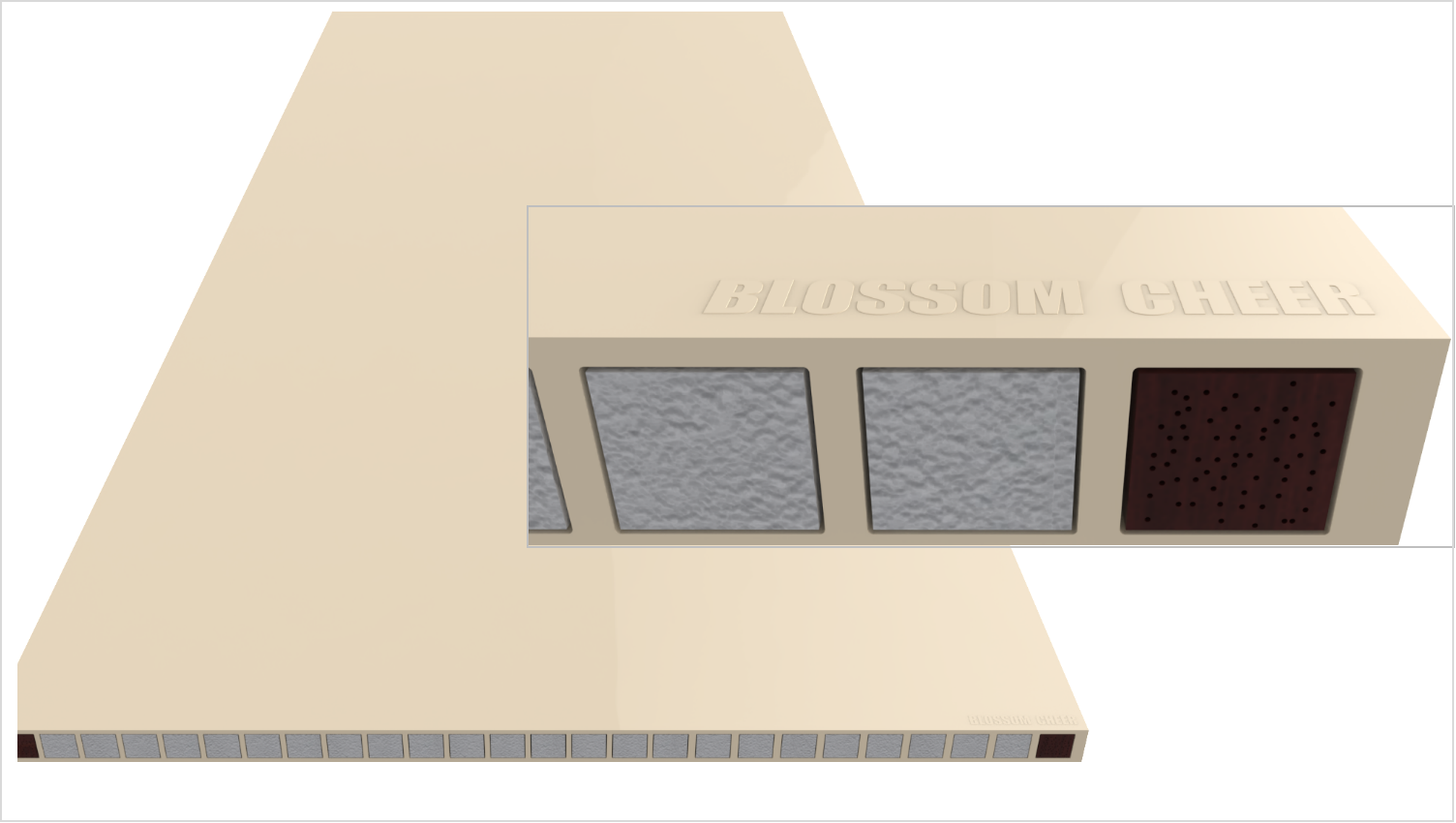

The overall structure of the door is made of pure wood-plastic material. At the same time, we recommend the use of hardware materials with better anti-oxidation, such as 304 stainless steel. Wood-plastic doors can be used in offshore areas with high humidity and salt, as well as in the Middle East with hot climate.

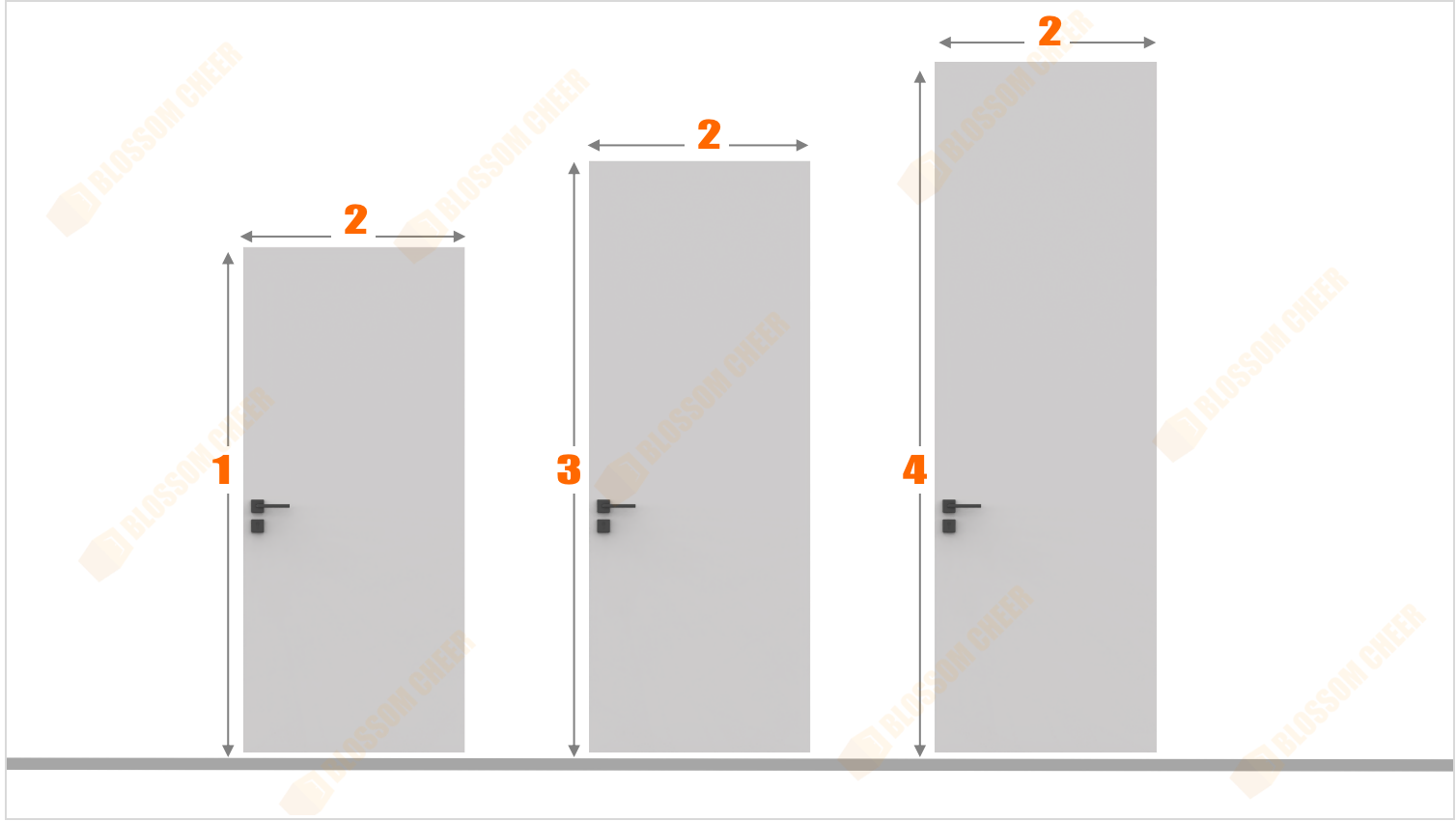

1. door panel standard height: 2050mm

2. door panel standard width: 700mm, 800mm, 900mm

3. door panel standard height: 2400mm

4. door panel standard height: 2800mm

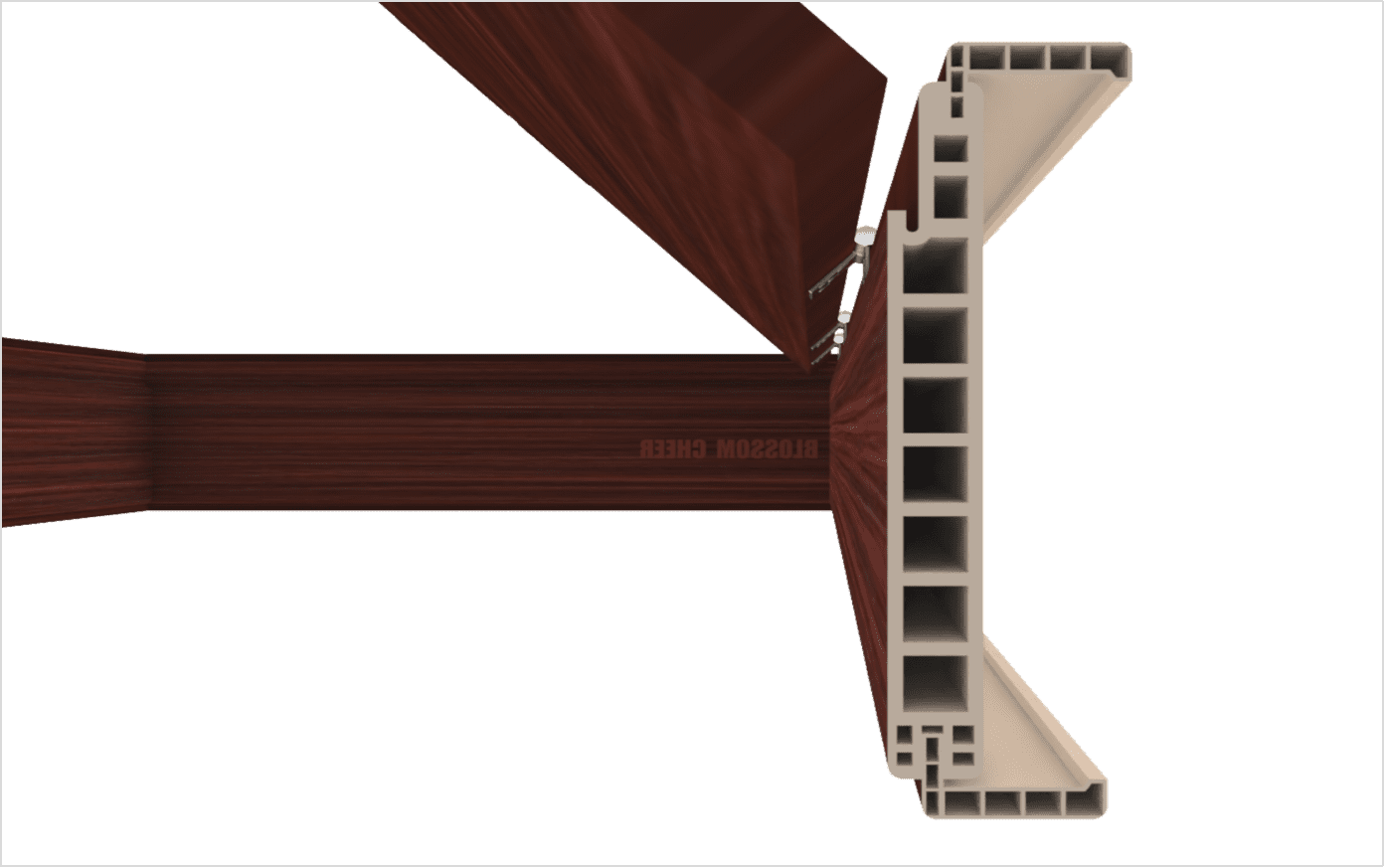

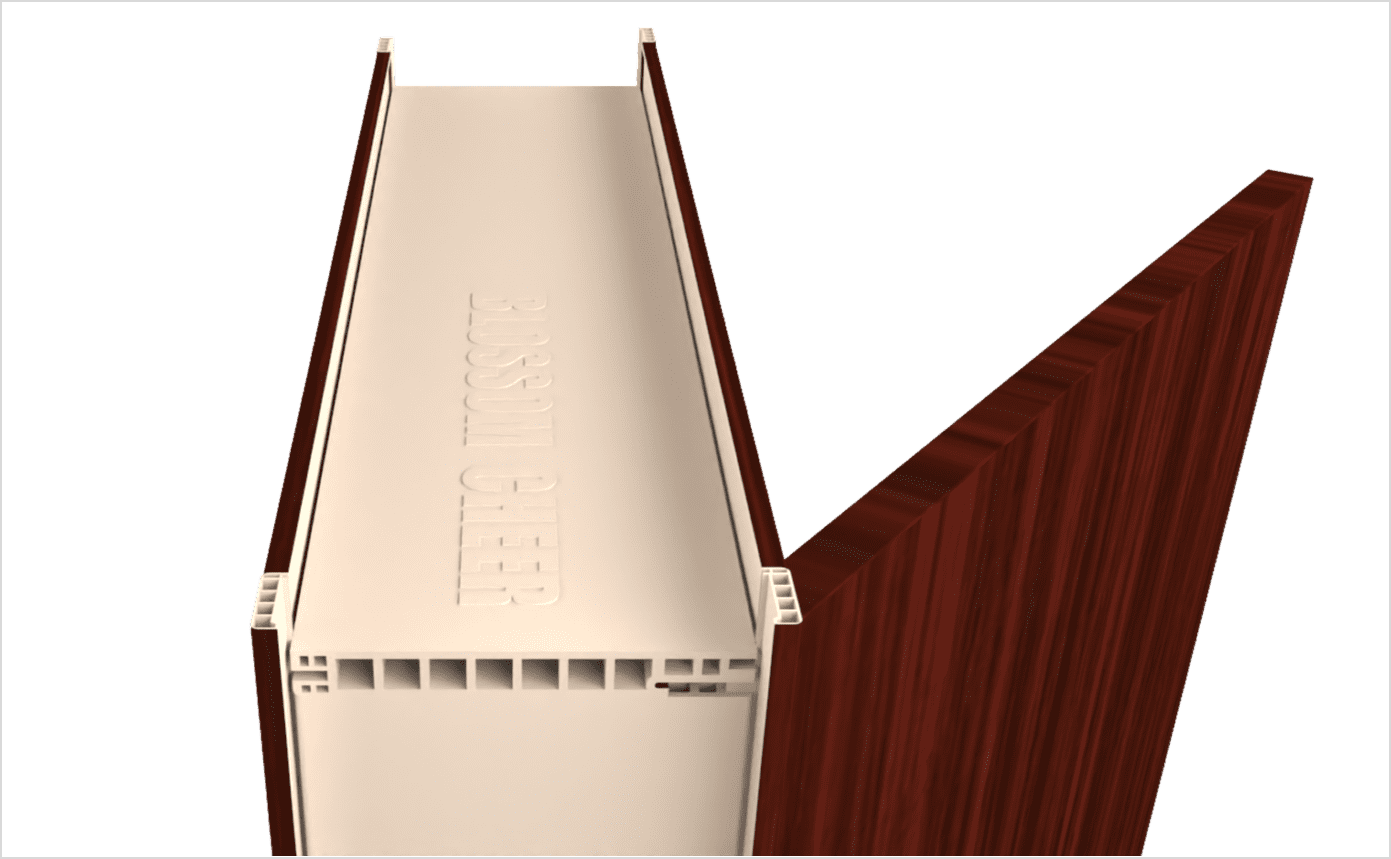

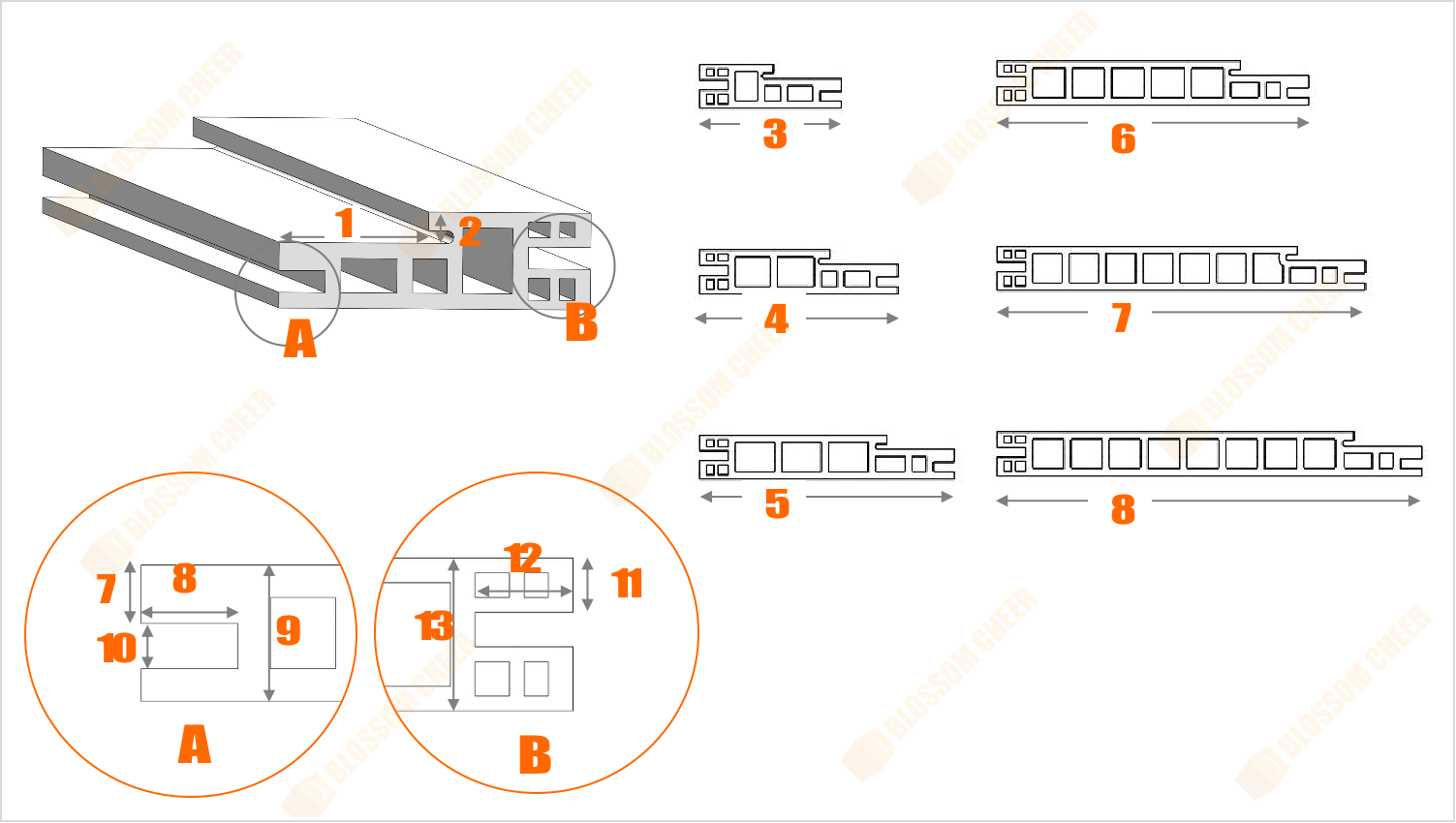

Enlarge the size and details of the gong groove (snap into the door sleeve), and explain it with parameters.

Cleaning WPC doors is a breeze! Use a soft cloth or sponge with mild soap and water. Avoid harsh chemicals or abrasive materials that could scratch the surface. Think of it as giving your door a gentle spa treatment!

It is not advisable to hang heavy objects on the door leaf. Otherwise, the door leaf will be skewed and the service life of the WPC door will be shortened.

Do not use sharp objects to scratch the surface of the door panel. The surface of the door panel is generally processed specially. If the surface is scratched during use, it will greatly affect the overall appearance.

Do not splash corrosive solvent products on the door leaf and door lock. These will cause damage to the surface of the WPC door.

To ensure your WPC door lasts for years, avoid exposing it to extreme temperatures and direct sunlight for prolonged periods. Treat it kindly, and it will repay you with long-lasting beauty and functionality.

When painting the walls, avoid painting the wall paint to make the door finish materials peel off and fade, which will affect the overall appearance.

WPC doors are not afraid of water, but if they are exposed to the sun for a long time, the raw materials will volatilize; if they are transferred or laminated, they will peel and crack. Therefore, WPC doors cannot be used outdoors, especially in places that are exposed to the sun for a long time.

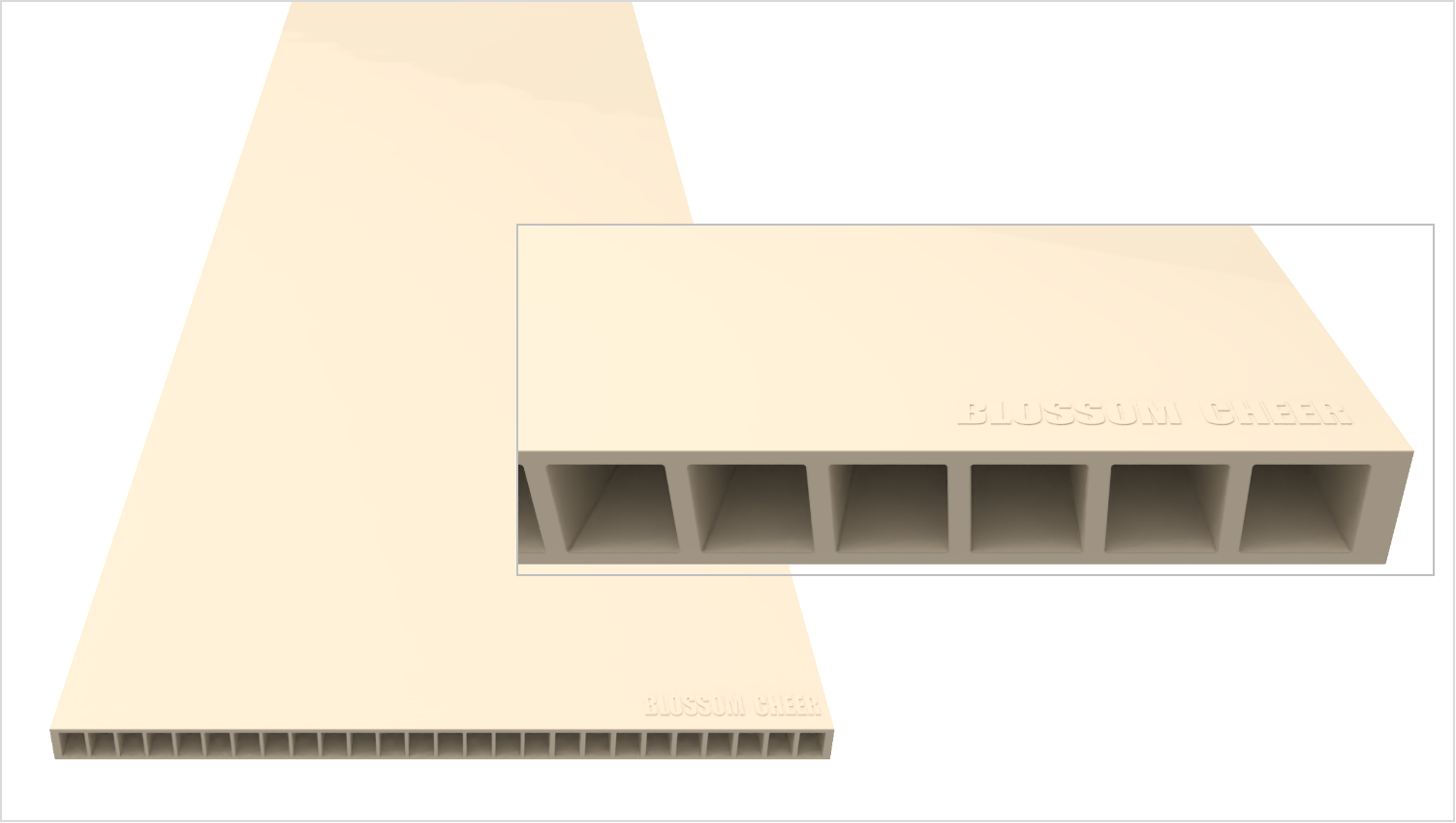

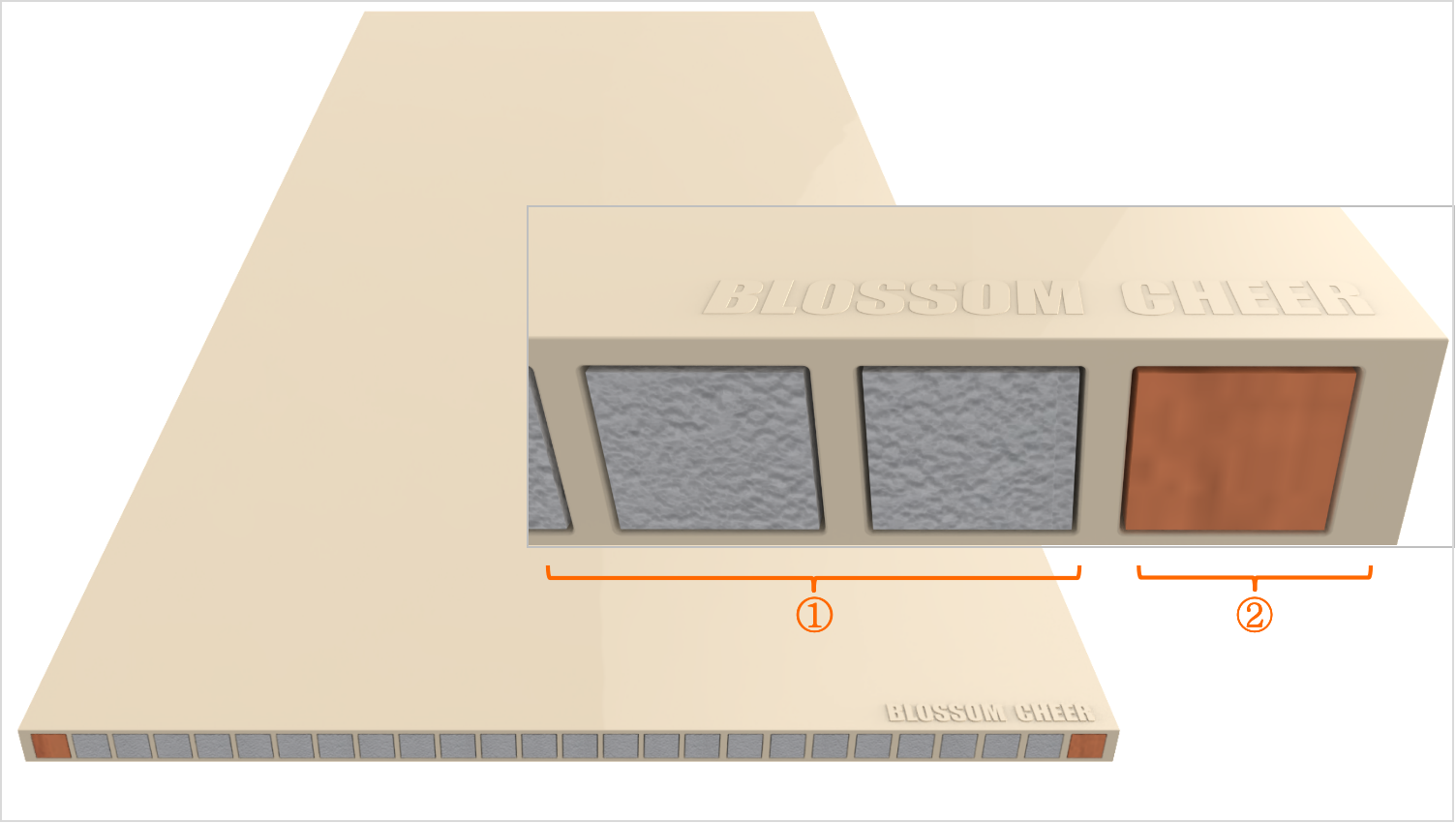

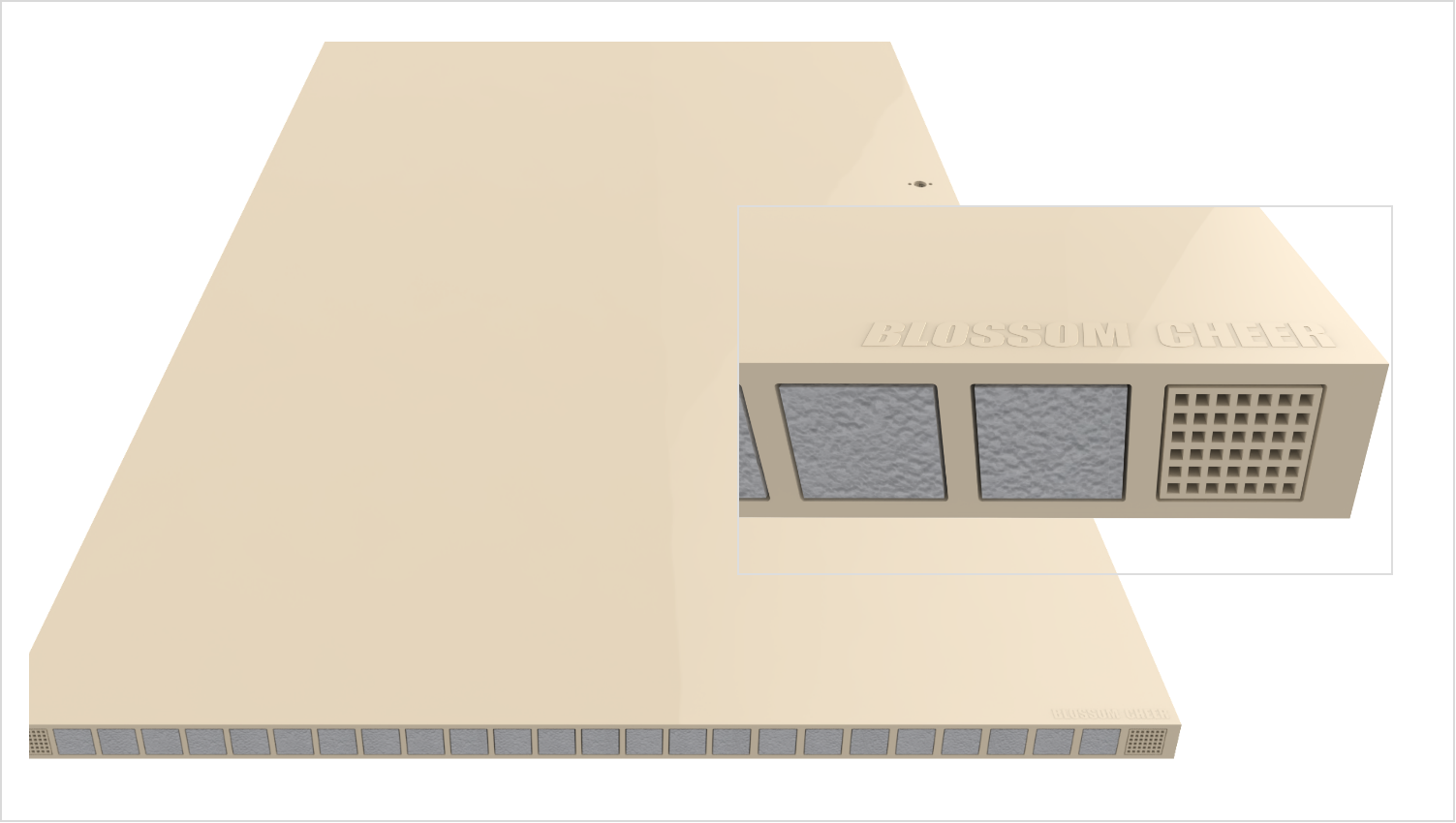

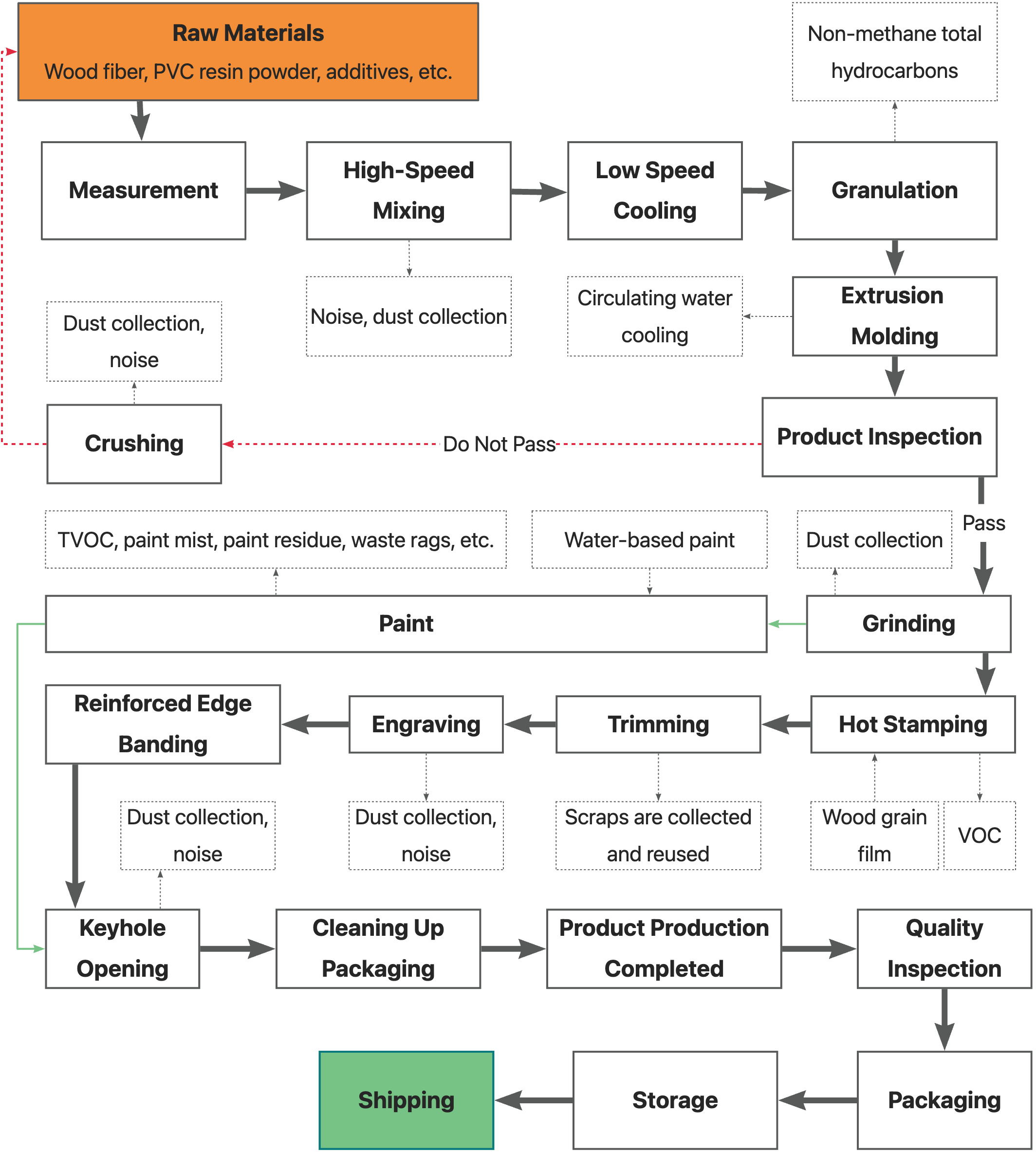

It is made by mixing superfine wood powder and polymer resin through molding process. It has both the excellent characteristics of wood and plastic, and the products produced have achieved the effect of real imitation wood. Since the raw materials used and the production process are not glued together, no harmful substances such as formaldehyde, benzene, ammonia, and polyethylene will be produced. It is a green and environmentally friendly new material that replaces traditional wood.

The molecular-grade resin powder contained in WPC door, after high-temperature foaming, completely wraps the wood powder to isolate water molecules. The water absorption rate of wood is about 12%, and the water absorption rate of WPC doors is less than 1%. Basically does not absorb water. The water absorption rate of BLOSSOM CHEER's WPC door is 0.3%, which is absolutely waterproof, and can even be used directly in water for a long time.

WPC doors are not mixed with any glue adhesives during the production process, so there will be no toxic and harmful substances such as formaldehyde, benzene, ammonia, etc., and it is a new green and environmentally friendly material. In our national standard, the standard requirement is ≤1.5mg/L, and the detection structure of BLOSSOM CHEER is ≤0.2mg/L, which also meets the EO level standard (European environmental protection standard), so the product is very standard and healthy. For more information, please refer to our test report.

The raw materials used in WPC door are formed under high temperature, high pressure and vacuum conditions. The material does not contain formaldehyde. The heat transfer technology is used in the secondary processing, free of paint, and no toxic and harmful gases and odors are released during production and use, so it is a human-friendly product that meets the environmental protection standards of modern interior decoration.

Since the WPC door is manufactured under high temperature and high pressure environment, it will not support combustion when it encounters fire, and has good flame retardancy and other characteristics. It should be noted that flame retardant does not mean that it can be used as a fire door. In case of fire or other situations, the WPC door is easy to soften when encountering high temperature, so it cannot be directly used for fire doors.

Waterproof, moisture-proof, anti-corrosion, mildew-proof, insect-proof, non-deformable WPC products have dual characteristics of wood and plastic, so WPC suit doors are not only used for indoor doors, but also suitable for places with large temperature differences, humidity, and poor ventilation , such as wet toilets, need anti-corrosion, mildew-proof, moth-proof storage rooms, etc.

With proper care, WPC doors can last 25 years or longer, making them a fantastic investment.

Absolutely! One of the significant benefits of WPC doors is their resistance to termites and other wood-boring insects.

Yes! You can paint WPC doors, but make sure to use paint suitable for plastic surfaces to achieve the best results.

For stains, a mixture of baking soda and water works wonders. Apply gently, scrub lightly, and rinse off with water!

No special hardware is needed; standard door hardware works perfectly with WPC doors, making installation easy and straightforward.

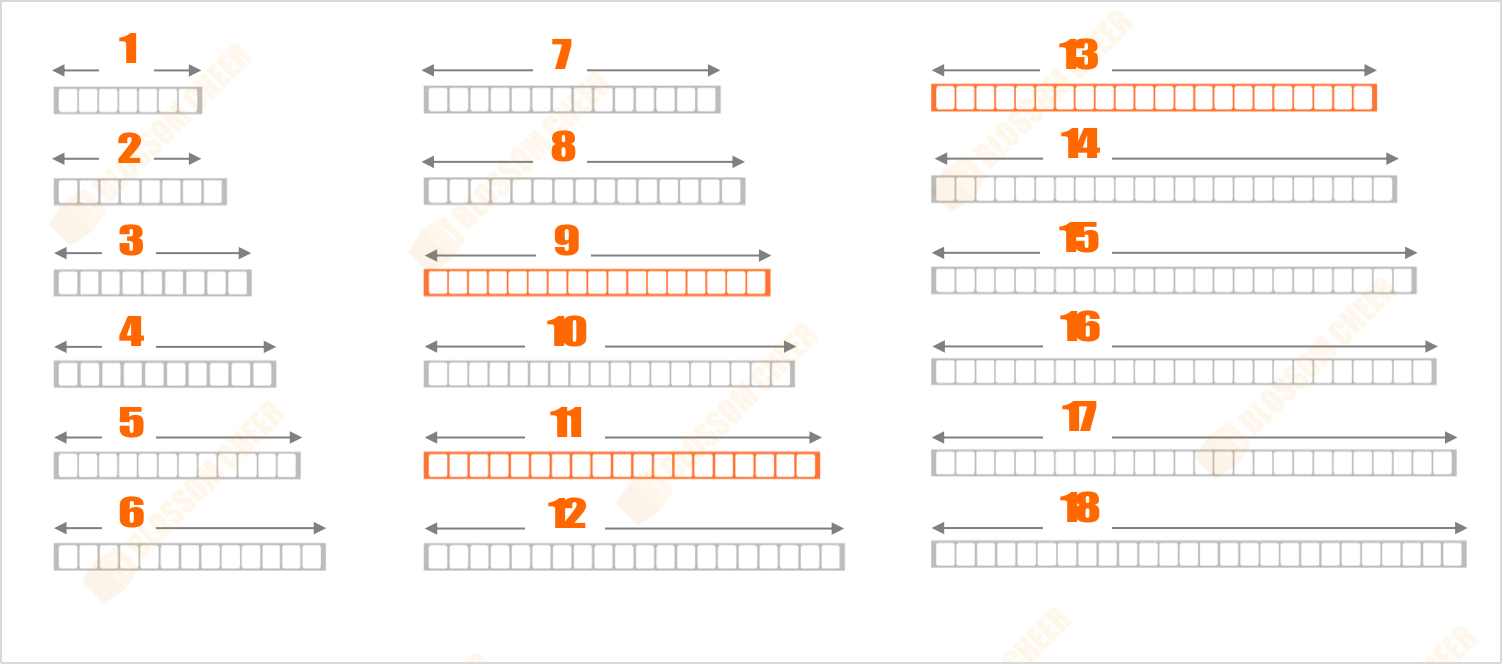

Project door size and quantity list, refer drawing or door style

Like design, color, materials etc., better share your refer drawing

Project positioning, construction progress, procurement plan, budget and other details, more specific information can help to make professional solutions.