General Features

• Environmental friendly

>>>meet RoHS - CE Environment standard

• Fast delivery

• Environmental friendly

• Fast delivery

• High cost performance

• Many colors and rich texture

• High cost performance

• Moisture-proof, flame-retardant

• Antibacterial, moisture-proof, colorfast

• Fire retardant

• High hardness, good wear resistance

• Rich textures and multiple choices

Videos for the entire paint-free product range will be updated.

RoHS-CE Environment Certificate

Melamine single-color doors are made into flat-panel styles using conventional standard melamine colors.

Melamine single-color doors are made into flat-panel styles using conventional standard melamine colors. Aluminum alloy decorative strips, etc. it can can also be added to the flat-panel style.

Melamine mould design door,is refers to the style design that already has a mold to make it, and the style and color have been fixed.

Carbon crystal single-color doors are made into flat-panel styles using conventional standard melamine colors. Aluminum alloy decorative strips, etc. it can can also be added to the flat-panel style.

Carbon crystal mould design door,is refers to the style design that already has a mold to make it, and the style and color have been fixed.

The HPL door has excellent wear resistance, corrosion resistance, heat resistance and waterproof performance, so it has been widely used in furniture, kitchen, bathroom, floor, wall decoration and other fields.

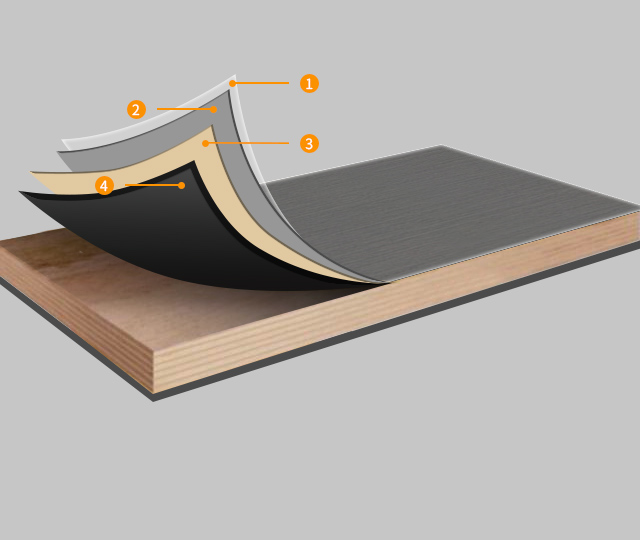

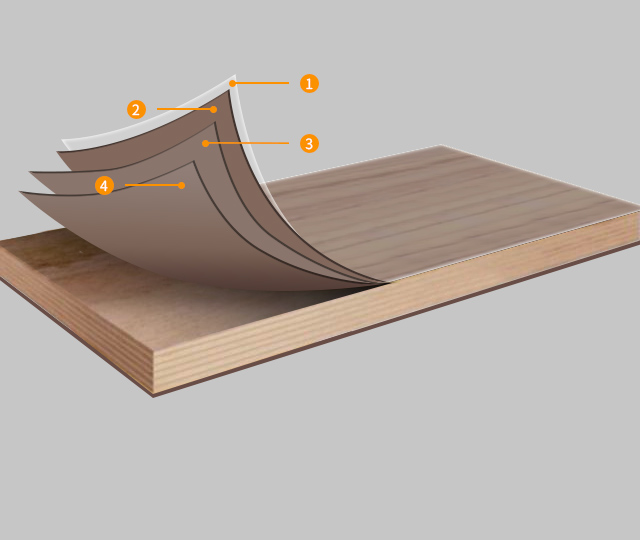

The three-dimensional view of the door leaf (also call door panel) shows different contrasts from top to bottom, including melamine veneer, HPL veneer, and carbon crystal plate veneer.

The perspective of the door leaf (also call door panel) section shows different contrasts from top to bottom, including melamine veneer, HPL veneer, and carbon crystal plate veneer.

Melamine material thickness range: 0.08-0.11mm (=0.0031-0.0043inch)

HPL material thickness range: 0.2-0.24mm (=0.0078-0.0094inch)

Carbon crystal material thickness range: 0.31-0.35mm (=0.0122-0.0137inch)

The above measurements are manual measurements. Because the production process involves plate pressing, there will inevitably be errors.

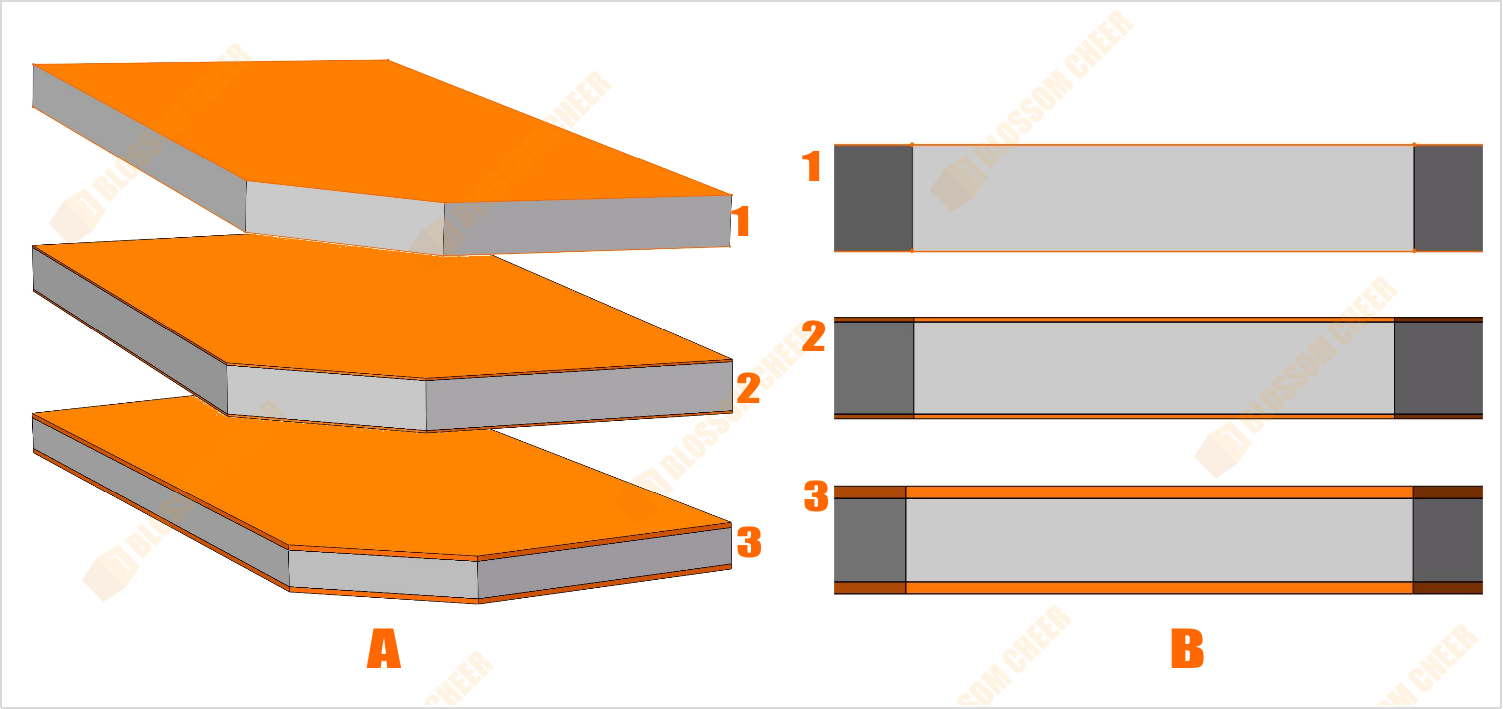

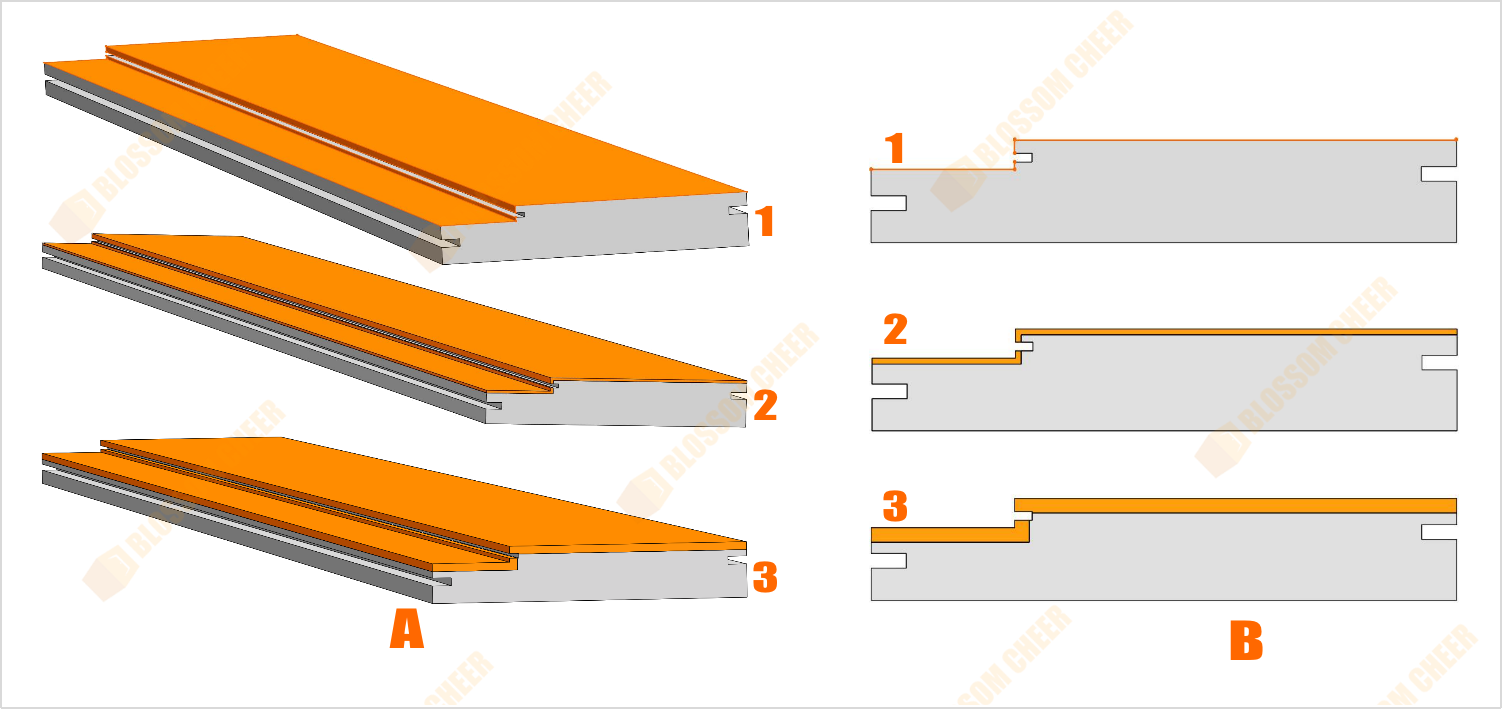

The three-dimensional view of the door frame (also call door jamb) shows different contrasts from top to bottom, including melamine veneer, HPL veneer, and carbon crystal plate veneer.

The perspective of the door leaf (also call door jamb) section shows different contrasts from top to bottom, including melamine veneer, HPL veneer, and carbon crystal plate veneer.

Melamine material thickness range: 0.08-0.11mm (=0.0031-0.0043inch)

HPL material thickness range: 0.2-0.24mm (=0.0078-0.0094inch)

Carbon crystal material thickness range: 0.31-0.35mm (=0.0122-0.0137inch)

The above measurements are manual measurements. Because the production process involves plate pressing, there will inevitably be errors.

Carbon crystal is a kind of microcrystalline carbon particles purified from minerals. It is high temperature resistant, corrosion resistant, and has a stable molecular structure. Carbon fiber board, waterproof, zero formaldehyde, and ultra-high density are high-end products worth having. Carbon crystal wooden doors , The wooden door made of this carbon element crystal as the material of the door leaf veneer, the inside of the door has solid wood, particle board (or plywood, Tubular Core board, etc.) composite materials.

Melamine doors are mainly wooden doors with melamine facing materials. This melamine facing material, through high-tonnage vacuum forming, produces a low-carbon, environmentally friendly, and beautiful door panel material.

High-quality door panels are closely related to the production process, glue quality and inspection standards. After the door panel material is made, the solid wood door leaf frame, internal composite filling material and door panel material are pressed into the door leaf by cold pressing equipment.

The door leaf also needs to be customized in terms of edge banding, lock opening, decorative style, etc., and matched with door frame, hardware, etc. to make a complete set of melamine wooden doors.

HPL, or High Pressure Laminate, is a new type of building decoration material whose main components are multi-layer cellulose paper and phenolic resin, plus a small amount of adhesives and additives. The Chinese name is fire-resistant board, also known as fire-resistant board, and its scientific name is thermosetting resin impregnated paper high-pressure laminated board. It is a refractory building material for surface decoration, with rich surface colors, textures and special physical properties. The material has excellent wear resistance, corrosion resistance, heat resistance and waterproof performance, so it has been widely used in furniture, kitchen, bathroom, floor, wall decoration and other fields.

Yes. Melamine veneer, referred to as melamine board, also known as veneer, also known as one-time forming board; it is made of base material and melamine-impregnated paper by high-temperature pressing. The base material includes MDF, particle board, moisture-proof board, and plywood. etc. Its biggest advantages are environmental protection, wear resistance, high temperature resistance, corrosion resistance, waterproof, simplicity and convenience, etc. It is the first choice for custom wooden doors and panel furniture.

1. The decorative effect is excellent. Its outer layer has a melamine paper film. The texture and color of this layer of film can be controlled according to people's needs. The color is bright and colorful, with various patterns, and the decorative effect is excellent.

2. Excellent physical properties, its smooth surface is a kind of product with balanced structure, not easy to deform, and excellent hardness. Compared with other materials, it has good wear resistance and dirt resistance, and can resist the erosion of ordinary acids, alkalis, oils and alcohols.

The manufacturing process of HPL is very complicated and requires multiple processes. Firstly, the multi-layer cellulose paper and phenolic resin are mixed according to a certain ratio, and then subjected to high temperature and high pressure treatment to press it into a board. The surface of HPL can be made into a variety of colors and textures, making it also have a good performance in decoration.

In the field of construction, HPL can be used in the production of walls, roofs, floors, etc., with excellent waterproof, fireproof, wear-resistant, antibacterial, anti-mildew, sound insulation, thermal insulation and other properties;

In the field of decoration, HPL can be used in the production of various decorative panels, door panels, partitions, etc., with rich colors and textures, which can meet the needs of different customers;

In the field of furniture, HPL can be used to make various furniture with good hardness and durability.

It is an environmentally friendly material that does not contain harmful substances and will not cause harm to the human body and the environment.

Easy to clean, just wipe with water or neutral detergent, no need to use special cleaning tools.

With antibacterial properties, it can effectively prevent the growth of bacteria and keep the environment hygienic and healthy.

It has good physical and decorative properties. It has high hardness and good wear resistance, and can be used in the production of various furniture, floors, wall panels, etc. At the same time, its surface can be made into a variety of colors and textures, making furniture and decorative materials more beautiful and decorative.

It has the advantages of fire prevention, waterproof, sound insulation and heat preservation.

Project door size and quantity list, refer drawing or door style

Like design, color, materials etc., better share your refer drawing

Project positioning, construction progress, procurement plan, budget and other details, more specific information can help to make professional solutions.